Spiral Welded Steel Pipes

Production Standards

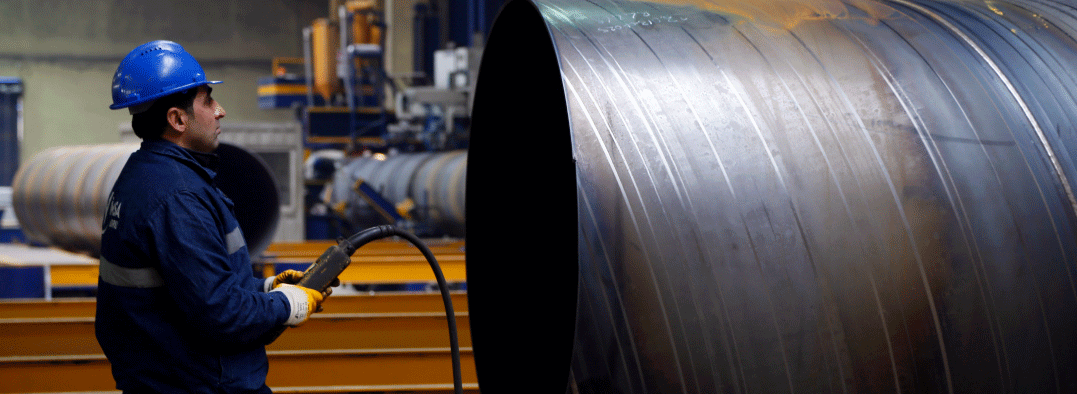

As the name suggests, spiral welded pipes are steel pipes produced by joining them with an automatic submerged arc welding method in a spiral form. Coils are flattened in strips and directed to rollers to be shaped into the desired form. The edges of the coil band, bent at a predetermined angle based on the pipe diameter, are joined in the most suitable way for welding.

Throughout the production line, internal and external welds are continuously inspected. First, internal, and then external, welds are joined with the submerged arc welding method. The weld areas of the sheet joined are 100% inspected with an automatic ultrasonic control system. After the coil band forms into a pipe, it is cut to the desired lengths with an automatic plasma machine. The following standards are applied depending on the areas of application.

Steel pipes may be exposed to corrosion due to external factors such as air, water, soil, and chemicals. Steel pipes are protected by coating them with a material inside and outside according to the intended use.